Overview

Phoenix Controls, a division of Honeywell International, designs and manufactures specialty venturi valves and control systems for research, life science, and healthcare environments. These valves allow for greater airflow control, thus providing cost savings due to lower energy usage and a safer/healthier environment for healthcare facilities.In 2010, Phoenix Controls contacted Carmel Software to co-develop a customized energy analysis software tool (PC Optimizer) for HVAC systems that could be used by their salespeople and customers to calculate the energy savings of using Phoenix Controls valves versus conventional HVAC valves.

This is a highly complex software tool that takes into account the properties of the building, the HVAC system type, airflow requirements, energy costs, initial equipment costs, and much more. All of this information is used to calculate the payback period of a HVAC system using a Phoenix venturi valve versus conventional VAV and constant volume systems. This software tool includes the following features:

- A wizard style user interface for easy navigation

- Accurate VAV modeling

- Alignment with various commercial building types

- Built in room types for quicker modeling

- Utilizes TMY3 and WMO weather data

- Includes what-if scenarios

- Flexibility for simple or more detailed energy analysis

- Flexible reporting on energy, sustainability, and ROI

Screenshots

(Click the images to display versions that are larger and clearer.)Startup form

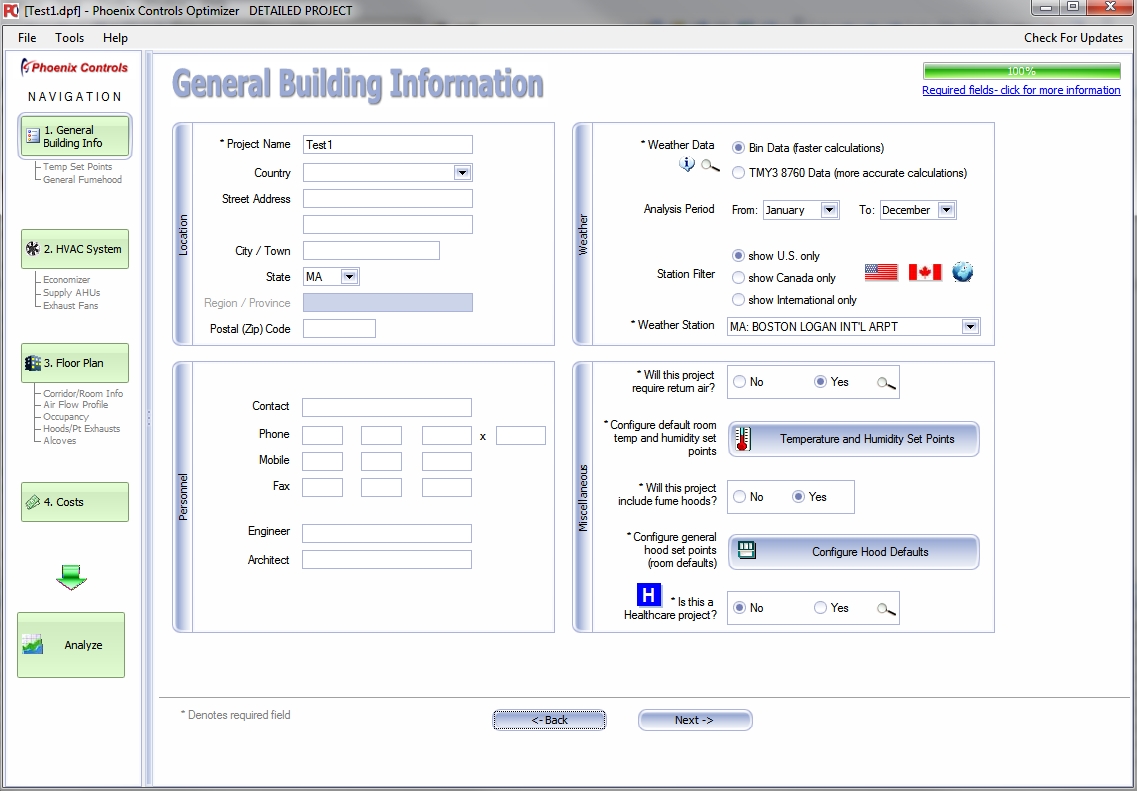

General Building Information

This is the first screen to appear after you start PC Optimizer, and it includes inputs for overall building information including:

- Location information

- Contact information

- Weather data selection (BIN or TMY3 8760 data) for 1000s of cities world-wide

- Other initial project settings

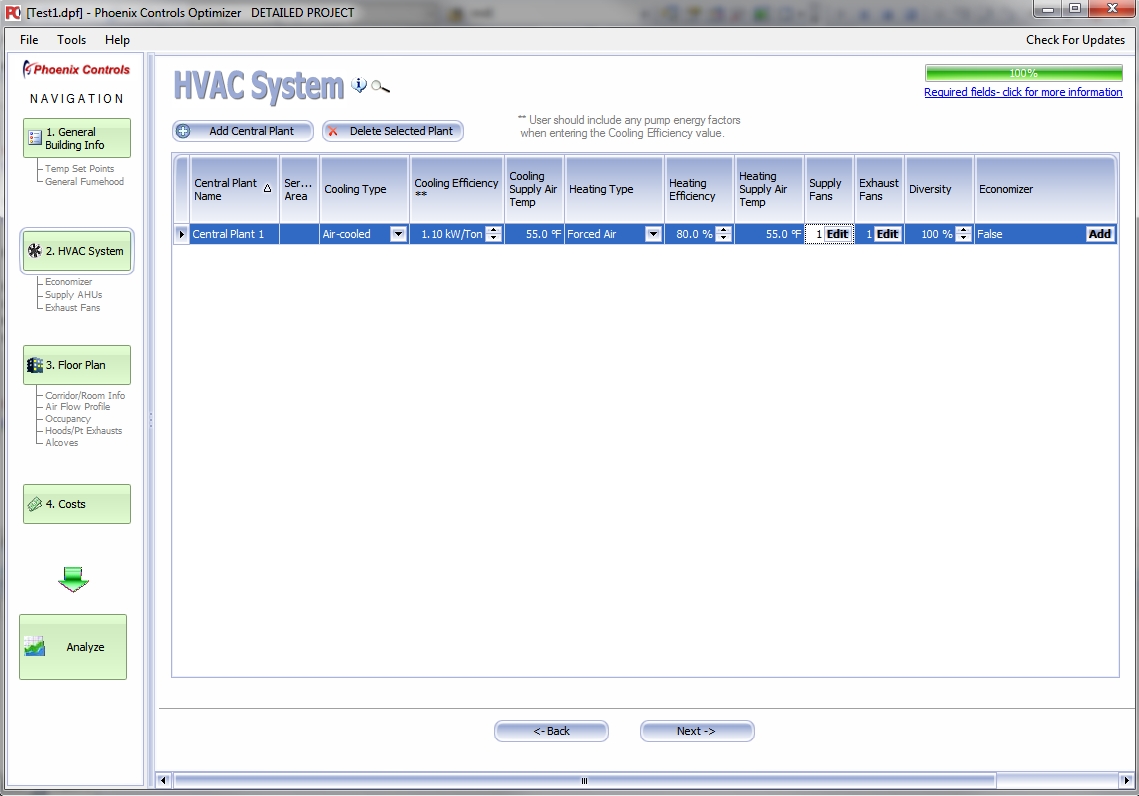

This screen allows you to input information related to the cooling and heating "plants" and supply/exhaust fans. It includes inputs for:

- Cooling and heating plant type and efficiency

- Cooling and heating supply air temps

- Supply and exhaust fan chacteristics including efficiencies and static pressures

- Diversity and economizer selections

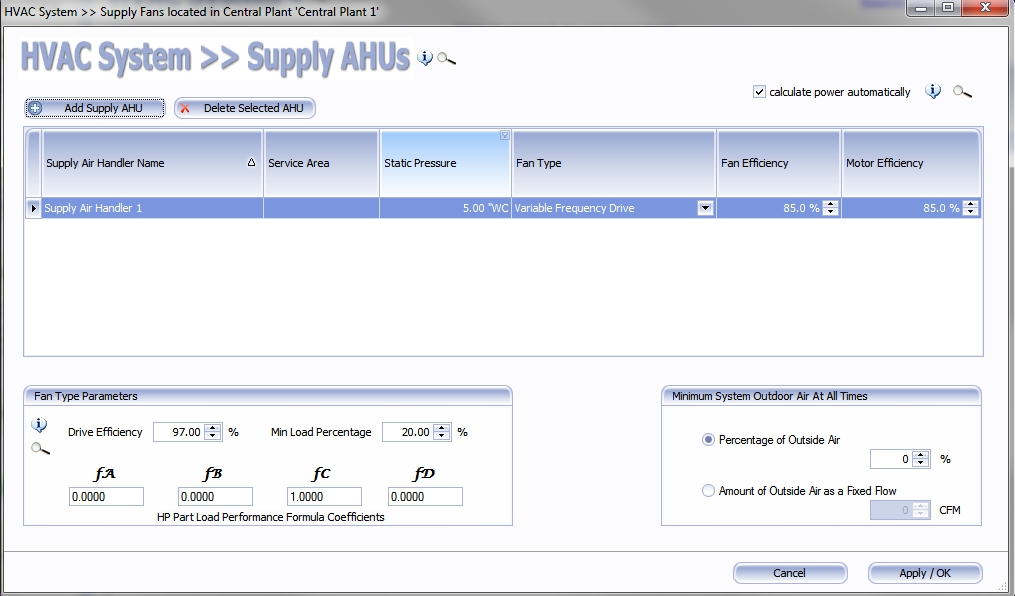

You can add 1 or more supply fans to a project. Later on, you can assign corridors and rooms to the different supply fans. Supply fan inputs include:

- Static pressure

- Fan type

- Fan effiency

- Motor efficiency

- Fan type parameters (for part-load curves)

- Minimum outdoor air requirements

You can add 1 or more return/exhaust fans to a project. Later on, you can assign corridors and rooms to the different return/exhaust fans. Inputs include:

- Static pressure

- Fan type

- Fan effiency

- Motor efficiency

- Fan type parameters (for part-load curves)

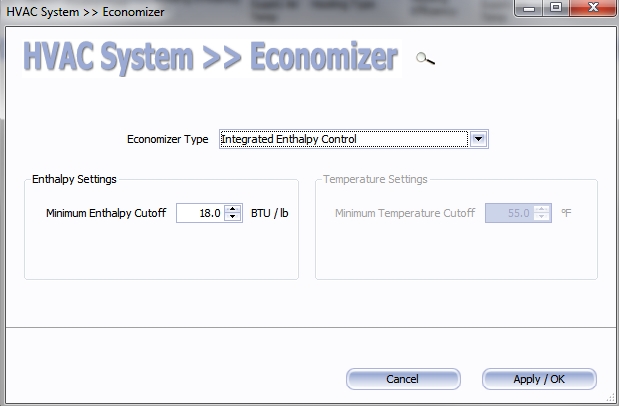

The economizer option is only displayed if the system includes return air. The economizer inputs include:

- Economizer type

- Cutoff enthalpy/minimum temperature